CSFMB©/CeSFaMBTM Comprehensive Simulator of Fluidized and Moving Bed equipment

ph: +55-19-997107134

dss

Services

It should be stressed that CeSFaMB is a comprehensive simulator that provides detailed information at each point throughout the equipment. Therefore, it is not a simple zero-order or black-box simulator, which assumes overall mass and energy balances and therefore capable of providing just equilibrium composition of exiting streams. CeSFaMB is a dimensional simulation and considers differential mass and energy balances for all phases throughout the bed (or dense region) and the freeboard (or lean region).

-

CeSFaMB - Comprehensive Simulator for Fluidized and Moving Bed equipment

CeSFaMB provides a complete picture of the internal processes such as:

- Concentration profiles of 18 gaseous components (Ar, H2, H2O, CO, CO2, O2, N2, CH4, SO2, NO, N2O, NO2, HCN, H2S, NH3, C2H4, C2H6, C3H6, C3H8, C6H6, Tar) throughout the bed (emulsion and bubbles) and the freeboard;

- Flow and temperature profiles of gases in the bed and freeboard;

- Temperature, rate of circulation profiles (or flow) of solid phase components in the bed and freeboard;

- Composition, particle size distribution of each solid species in the bed and at each point of the freeboard;

- At each point of the equipment, all parameters related with the dynamics of the bed and freeboard. Among them: bubble diameters, upward velocities of each phase (emulsion, bubbles, particles), minimum fluidization parameters, rate of particle turnovers, etc.;

- In the case of recycling of solid collected by the cyclones, all parameters describing such an operation, as well its effects in the process;

- Profiles of important homogeneous and heterogeneous reaction rates. This feature provides a clear picture for deeper understanding of the processes occurring at each point of the equipment.

- All engineering parameters to help with equipment design as well as optimization of operations. Among these parameters there are: carbon conversion, efficiencies, pressure losses, bed holdup, residence times of particles, rate and characteristics of entrained particles, parameters to allow verification of segregation of particles in the bed, etc.;

- In the case of boilers, important operational parameters regarding the heat transfer to immersed tubes are also provided. Among them: detailed temperature profiles of the immersed tubes in the bed and in the freeboard, flow, temperature, and pressure of produced steam, heat transfer rates and coefficients related to the tubes and bed iteration, rate of erosion of tubes immersed in the bed, efficiencies, etc.

- All process parameters to allow evaluations and studies of equipment concepts such as, for instance, use of water jackets for steam generation, which can be injected at any point of the reactor, use of gas jackets for pre-heating of air or gasification agent before it is injected into the bed.

- In the case of gasifiers, several details and parameters are also provided. Among them: “Cold” and “Hot” efficiencies, flow, composition, temperature and pressure of the produced gas at various basis (molar, mass, wet, dry), physical and chemical properties of the exit gas (heat values, heat capacity, density, conductivity, viscosity, adiabatic flame temperature in air and in oxygen).

In addition to these possibilities, the latest version allows:

- Simulating cases where two or more fuels are simultaneously fed into the equipment.

- Simulating equipment with almost any geometry. The user would be able to input various internal diameters according to the vertical position; for instance, a reactor with many conic combined with straight walls. CeSFaMB can simulate even equipment with curved vertical walls.

- Proper design of the reactor's internal and external insulation layers. The user would be able to input the thickness and thermal conductivity of various insulation layers. CeSFaMB would compute the temperatures of interfaces inside the composed layers as well as the external surface temperatures with great precision. Such would permit proper and secure design of insulations to avoid risks to the reactor steel shell.

The computational code provides several warnings against dangerous or impossible operations. These warnings are extremely important to avoid accidents or destruction of the equipment. Examples of problems more related to bubbling techniques are:

- Collapse of the bed due conditions below minimum fluidization;

- Total carrying of the particles or state of pneumatic operation;

- Eventual surpassing of softening ash temperature, which provokes agglomeration of particles and collapse of the bed. This problem could destroy the refractory insulation of the reactor;

- Slug-flow due to bubbles reaching dimensions comparable to the cross-section of the bed.

- Segregation between particles in the bed. As shown before, this process may lead to non-uniform temperatures and bring problems such as bed collapse or excessive tar concentration in the exiting gas.

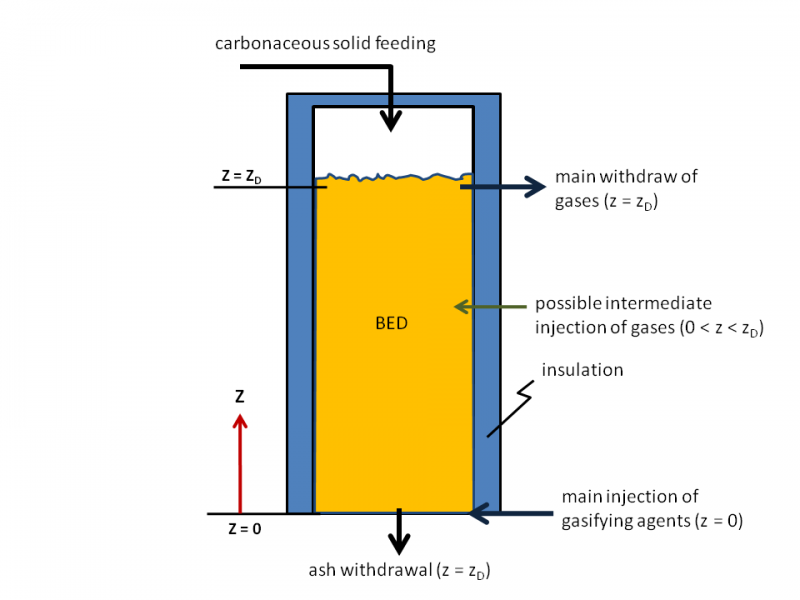

Basic scheme of CSFMB mathematical model

Scheme of bubbling fluidized bed boiler or gasifier

Scheme of bubbling fluidized bed boiler or gasifier Scheme of circulating fluidized bed equipment

Scheme of circulating fluidized bed equipment

Scheme of updraft moving bed gasifier

Scheme of downdraft moving bed gasifier

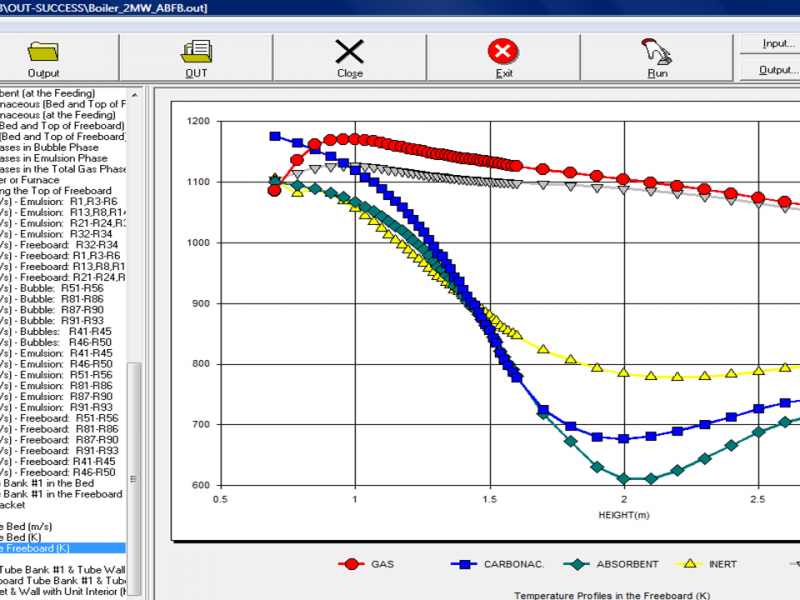

Typical graph produced by the interface

Typical graph produced by the interface

Aspect of control panel for output page

CeSFaMB comes with a easy-to-use graphical interface

- Easy to input data

Aspect of a CSFMB interface input page

Aspect of an output page

Aspect of an output page

CeSFaMB has been tested against the following industrial and testing units:

- Babcock & Wilcox (USA) bubbling bed boiler demonstration unit burning bituminous coal.

- National Coal Board (United Kingdom); bubbling bed boilers consuming bituminous and subbituminous coal.

- Grimethorpe Unit (United Kingdom); pressurized bubbling bed boiler unit consuming coal.

- IGT -- Institute of Gas Technology (USA), RENUGAS® process (pressurized bubbling bed gasification using pure oxygen and steam), consuming wood and sugar-cane bagasse.

- IGT -- Institute of Gas Technology (USA); pressurized hydroretorting of oil shale.

- University of British Columbia (Canada); atmospheric circulating bed gasifier consuming biomass.

- Various pilot units testing combustion and gasification of various coal and biomass.

- New features allow simulation of unusual cases. For instance, the case of pilot tests carried at University of California at Davis could not be properly simulated by the former CSFB model because the pilot operated with supplemental electrical heating. However, the new version (CSFMB) already provides for that possibility and has successfully reproduced the results. A copy of the paper in the FUEL Journal in that regard can be sent to those interested.

- The newer CeSFaMB generation includes the following features:

-

Simulates operations where many different fuels are simultaneously fed into the equipment. Such would allow predicting the operational details of boilers, gasifiers, and other processes when various mixtures of fuels (for instance, coals and biomasses) are consumed.

-

Simulates equipment in any shape, i.e., those with various diameters or cross-sectional areas throughout the equipment height.

-

Computes the temperature at insulation layer interfaces as well interface-metallic shell layers. This allows verifying if unsafe temperatures for the shell have or might be reached as well provides more precise computations of heat losses to the environment.

-

Faster processing of cases with improved precision.

Comparisons between experimental and simulation results have led to average deviations below 5% at all important process parameters.

CeSFaMB package includes a set of data and results for several situations, including the above mentioned. Complete manual and technical assistance are also provided.

.